Growing Blog

Using Pressure Cookers for Growing Mushrooms

If you ‘re wanting to grow mushrooms at home, you need to get yourself a dependable pressure cooker.

There’s really just no way around it.

You see, fighting contaminates is a constant battle. The cultivator needs to be aware of potential sources of contamination, and how to prevent the bad guys from getting a leg-up on your mushrooms.

Naturally, things like rye grain, malt extract agar and supplemented sawdust blocks are home to all sorts of contaminates. Mold spores, bacteria, and other nasty bugs are just waiting patiently… biding their time until a little warmth and moisture allows them proliferate and take over.

Basically, these contaminates are evil, and must die- which is a task that is easily accomplished with a good pressure sterilizer.

How Do They Work?

We don’t have to dive too deep into the principles of thermodynamics, but it does help to understand the basics.

Most people know that at atmospheric pressure, water can only get so hot before it turns into steam. So, if you tried to sterilize your substrates by using a stock pot full of boiling water, your substrate would never be able to get warmer than 100 °C.

Unfortunately this isn’t quite hot enough. In fact, many contaminates can survive being subjected to this temperature without breaking too much of a sweat.

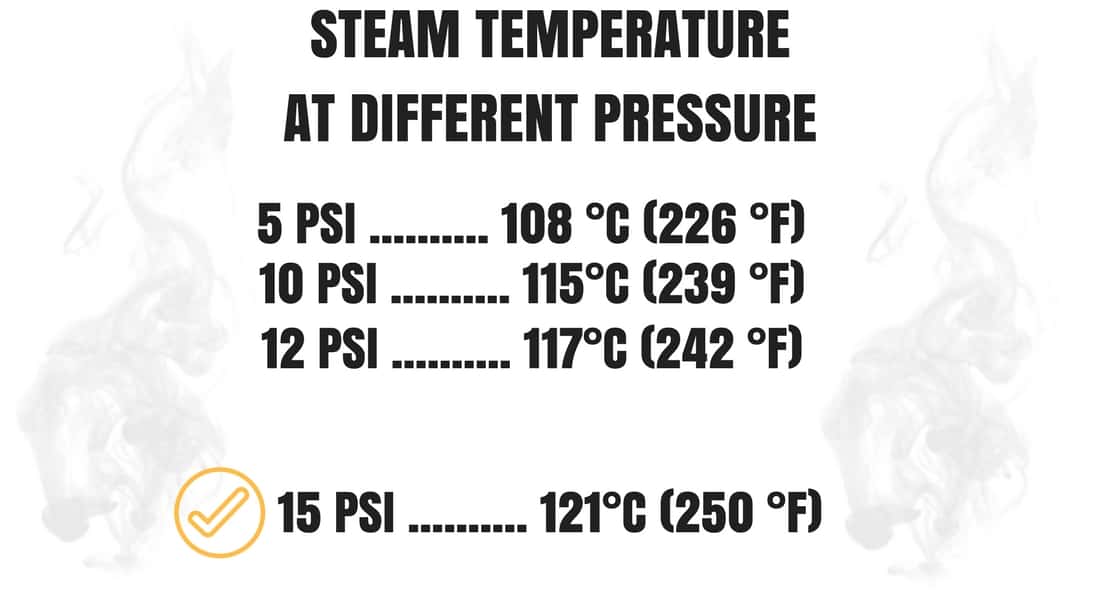

Even if you put a lid on the stock pot, the steam just can’t get any hotter than 100 °C. However, under sustained pressure, water is able to remain in a liquid state at much higher temperatures. In fact, the temperature of the steam goes up in direct relation to the increase in pressure.

A pressure cooker works by preventing steam from escaping the pot until a certain amount of pressure is built up, allowing for the water to become hotter than it otherwise could. There are many different styles, but most operate by using a small weight that sits on a vent on the lid of the cooker. As the pressure builds, the steam is eventually able to overcome the weight on the vent.

In this way, a stable pressure and an elevated temperature are maintained.

When sterilizing things like substrates, grain and agar mixes, you want to look for a pressure cooker that can maintain a pressure of 15 PSI, which allows for steam temperature of 121°C- hot enough to kill pretty much anything you need to worry about.

Many people will ask if they can go with lower pressures. Is 12 PSI ok? Can we get away with 5 PSI? The answer is… maybe. Generally if the pressure is lower, full sterilization can still be accomplished only if sterilization times are increased. If you are in the market for a pressure cooker, you should look at getting one capable of 15 PSI.

Using a Pressure Cooker

Recently, I managed to mess up pretty bad using my pressure cooker, and I’m not afraid to admit it.

It was late at night, and I was sterilizing some grain in mushroom grow bags, with the intention of making a whole whackload of second generation spawn. I was tired, and didn’t feel like staying up until the sterilization was complete, so instead, I decided to set an alarm for the end of the cycle, and go to sleep.

I woke up about an hour later, before the alarm went off. As the fog of sleep started to clear from my mind, I realized that I couldn’t hear that familiar jingle-jangle of the cooker. Immediately, I jumped up and ran to the kitchen to turn off the stove, but it was too late. The pressure cooker had run out of water, and the grain bags had melted right through.

A real disaster… although it could have been worse.

This incident forced me to start over, but also made me realize that I should take more care when using this equipment.

Although pressure cookers are simple, they are still serious pieces of equipment. If operated without care, they could turn into bomb with the potential to cause serious injuries. It makes sense to take the proper steps when running your pressure cooker.

So here the right steps and some tips for using a pressure cooker the right way:

- Check to make sure that the seal is in good condition, and that there is no warping or other signs of wear on the cooker. The rubber seal can degrade over time, causing the cooker to leak as it is building pressure. Some cookers do not have a rubber seal, so if that is the case you can skip this step.

- Ensure that you are using a stove that can withstand the prolonged heat and the weight of the cooker. Some people can have issues with glass top stoves, depending on the size of the sterilizer.

- Fill your cooker with your substrates, grain, or agar, and fill with an adequate amount of water. You want enough water to last the full duration of the sterilization process. You will learn how much water is enough over time- just pay close attention for the first few runs.

- Bring the temperature up to maximum and let the cooker pressure up. This could take a really long time, depending on the size of your cooker.

- Once the pressure has built up enough to overcome the force of the weight, the weight will start to jiggle, and steam will be released. Leave the stove on max for another minute of so, and then turn down the stove to medium or low. You want just enough heat so that the steam barely has enough pressure to move the weight.

- Once the time is up, shut off the stove and walk away. It is way too hot to deal with for a while. I usually like to leave it overnight. There is no need to rush and pull the bags out right away. The exception is if you are pouring agar plates, in which case you want to remove the agar before it has solidified. Usually you will still have to wait over an hour though.

- Once the pressure cooker is cooled, you can remove you substrates or grain jars and inoculate!

Things to Avoid

Running Out of Water

As described above, running out of water can be a bad thing. As long as there is a threshold amount of water left in the cooker, the temperature inside will be limited to the temperature of steam at that pressure. Once all the water has boiled off however, the inside can reach extreme temperatures and melt or burn whatever is inside. Mushroom grow bags have a high tolerance to heat, but without water, all bets are off. You can also damage your cooker by overheating it in this way.

You will get a feel for how much water is enough over time. Just watch the cooker closely the first few runs, and if you notice that steam stops coming out of the vent, turn it off right away, and let it cool down. You may be able to save your substrates from burning or melting if you catch it fast enough.

You also want to ensure that you don’t put too much water, so that the water doesn’t leak into your jars or bags and change the moisture content of your substrates. Check potential entry points into your substrates (such as filters or holes in the lid) and make sure the water will stay below this.

Blocking the Vent

Pressure cookers are designed to release steam though the vent once a certain pressure has been reached. However, if the vent is blocked for some reason, the pressure will continue to build. If the safeties are also blocked, or fail to open for one reason or another, you have a very dangerous situation. The pressure may continue to build until the cooker literally explodes, filling the kitchen with hot steam and shrapnel.

This is why it is important to make sure that the vent is not blocked from built up gunk, or other debris. Be sure that a safety vent is also in place. I like to place a firm object, such as a plate, on top of mushroom grow bags inside the cooker so that the bags aren’t able to flap up and block the vent.

Also, be sure to never add additional weight to the vent in order to achieve a higher pressure. Your cooker is designed to withstand the pressure from created by the supplied weight- and you should never mess with this!

Using the Wrong Heat Source

The best types of stove to use for pressure cookers are usually coil top or natural gas stoves. Glass top stoves could be damaged from the weight and the slight vibrations of the cooker. Usually the worst that will happen is minor scratches in the glass, but pressure canners have also been known to break the glass top entirely.

Also, never use your pressure cooker on a large outdoor propane burner. Honestly, I don’t really know why – but any manual I have ever read on pressure cookers has made this fact abundantly clear. My guess is that it is just too much heat, and could warm the bottom of the cooker, causing it to balloon out- compromising the pressure containing ability of the cooker.

How Long to Sterilize?

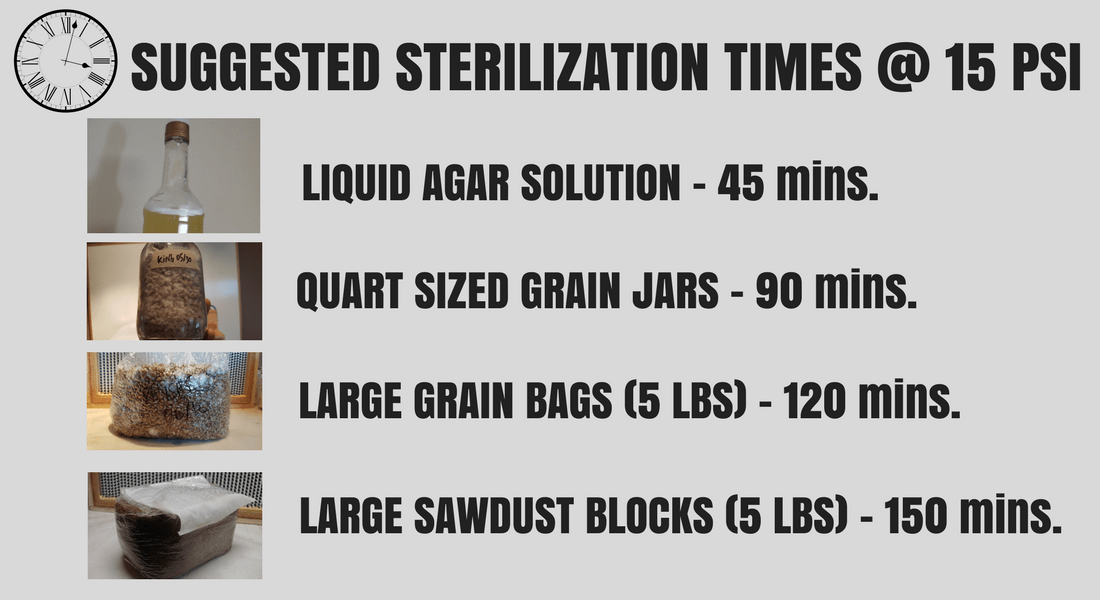

Most substrates, grain, and agar need a Pressure of 15 PSI in order to completely kill off any potential contaminates. At this pressure, steam reaches a temperature of 121 deg C.

The differentiating factor then, is the amount of time it takes for heat to fully penetrate to the center of the substrate in which you are trying to sterilize.

This makes sense when you think about it. A bottle of agar mixture goes into the cooker in a liquid state, and it takes no time at all for the whole mix to heat up. With a sawdust fruiting block however, the outside of the block will act as insulation keeping the center of the block cool for quite a while- and therefore needs more time to become fully sterilized.

Of course, this can vary depending on how big your pressure cooker is and how stacked together your bags are. If you have a large autoclave that can hold dozens of bags, it may take even longer for the heat to reach the center, and you may need to leave a good amount of space between the bags.

For most stovetop pressure cookers, however, the above times serve as a good guide.

Make sure that you don’t start counting the time until the cooker has reached 15 PSI. Some cookers can take up to 20 minutes to reach full pressure, and you wouldn’t want to cut your time short by including the heating up period.

Best Pressure Cookers

Unfortunately, pressure cookers are a bit of an investment- but if you are into growing mushrooms, it will be worth every penny. There are a number of different options depending on how much you want to spend.

The Best Value Pressure Cooker

It really is hard to go wrong with the Presto 23 Quart Pressure Canner. Many people will try and say bad things about the quality and the fact that it is made of cheap aluminum, but honestly I have used this exact canner countless times and it has never let me down.

The canner can hold 10 Quart sized mason jars (7 standing up, 3 on top laying sideways) and 4 large mushroom growing bags each holding 5 lbs of sawdust or grain. There is also a tray at the bottom to hold your jars or bags off the bottom.

The lid easily snaps into place, and there is a handy gauge on top so that you can easily watch the pressure build up towards the desired 15 PSI.

The downside to this cooker in my opinion is the fact that it has a rubber seal. Although it can last a surprisingly long time, it will eventually break down and crack, allowing steam to leak out the side and preventing any pressure from building up. At this time you would need to replace the seal, or move on to another cooker. You can get replacement seals for pretty cheap.

The Best Quality Pressure Cooker

OK, I’ll admit, the All American 921 21 Quart Pressure Canner is expensive… but just look at it:

This is a top quality piece of equipment that will last a lifetime. There is no rubber seal to break down, and the aluminum body is much more heavy duty. But it is more than twice as expensive as the Presto.

The lid is a little more complicated, with 6 separate knobs that need to be tightened. You may also have to apply a wax (lip chap works) between the metal to metal seal of the lid and the pot in order to maintain a tight seal.

The All American is also available in a number of different sizes. The largest one can hold 19 Quart jars, and 6 large mushroom grow bags, a total of 30 lbs of substrate is a single run. Not too shabby!

If you are serious about growing and you want nothing but the best, you should consider getting an All American canner for your sterilization needs.

A Stoveless Option

If you have the cash, and don’t want to have constant rattling noise in the kitchen, consider getting a complete sterilizer unit.

All American makes electric sterilizers in various sizes that can be set anywhere, and come as a complete unit. It is the same design as the other AA canners, but there is an electric heating unit built right in. All you need to do if fill it with water and plug it in.

Keep in mind that you will still need to set it down on something that isn’t affect by heat, such as a concrete floor or bench. Also, keep in mind that many of these units require 220 V ( the same power as your stove) while most, if not all, of your outlets will only provide 110 V. They do sell units that operate on 110V, but this will draw a lot of current and are likely to overload a circuit and blow your fuses.

Beat Contamination

A good pressure sterilizer / pressure canner is the only way to truly get a leg up on contamination before it even gets a chance. Without proper steam sterilization of grain, agar and other substrates, chances of success are low. But with the right equipment, you’ll be able to consistently eradicate contaminates, and have full confidence in the viability of your sterilized material.

Is there any chance you could do an article on various types of contamination and what to do when contamination strikes or how to avoid these sorts of problems? I’ve had contamination issues with my grain jars. Initially it was green mold, but that was conquered by changing filters to poly filling. I notice that sometimes I get some wet looking grains that have a milky residue around them in the middle of the jar before the first shake. I think it’s bacteria and I’m not sure if I should see if (for example) a pink oyster mycelium can out-compete it or if I should just throw it out and start over.

That is a great idea thanks for the suggestion! Maybe send some pictures, or post some of your contamination problems in the Mushroom Growers group? Milky residue around grain definitely sounds like bacteria. Are you using liquid cultures? How long are you sterilizing?

I’d be delighted to do that..which mushroom growers group are you referring to? I was previously sterilizing at 13psi for 2 hours, but now i’m sterilizing at 15 psi for 90 minutes. I’ve been going from sawdust spawn to grain (rye) for pink and warm blue oyster, but will be switching over to liquid culture in the coming weeks to triangulate the source of contamination. maybe this is related, but i use the metal jar lids with a hole drilled in them, with polly stuffing in the hole. I’ve found that the jar lids are nearly impossible to open after sterilization…it actually hurts my hands to open them. do the jars have to be sealed extremely tightly before pressurization or is a looser fit more conducive to decontaminating the lip of the jar? thanks for your response!

Hey Kaya, the group I am referring to is a facebook group that I am trying to put together (https://www.facebook.com/groups/mushroomgrowers)- if you don’t have Facebook, don’t worry about it we can still connect through email ect….

It sounds like you are on the right track. I use the same metal jar lids with a hole and poly stuffing. I almost never have contamination if I am sterilizing for 90 minutes at 15 PSI. I am guessing you cultures are contaminated or it is becoming contaminated while you are inoculating the grain. The jar lids do not have to be all that tight, not sure why they are seizing up on you? Maybe try a different style of jar? Is it the gasket part or the actual ring that is tough to remove? If it is the lid, you could try putting it on metal side down, this usually makes it easier to remove. Hope that helps!

Thanks for the response Tony! Let’s see…my sawdust spawn distributor just informed me that it is not a good idea to go from sawdust to grain. I’m not sure why. So the master sawdust bags are not showing any sign of green mold or bacteria, but the inoculated jars are showing signs of both. These results in from the 13 psi for 2 hours. I’m letting a warm blue oyster run right now that was sterilized for 90 at 15 psi. half the jars have been inoculated and the other were not to. Maybe this will elucidate the source of the contamination. How do you recommend cleaning out the contaminated jars? Should I soak them in diluted bleach and replace the poly filters (not sure what concentration would work here)? Furthermore, I run an ionizing hepa filter in my lab as well 24/7, but do you have a suggestion for deep cleaning the lab? A fellow brewer recommended using Detol and/or vinegar. I also have an central AC duct that cools the lab area…not sure if this is a corhigeable source of contamination either.

I have been tightening the wide mouth jars as much as I can before putting them in the canner. Perhaps to the point of resistance and then a slight twist more will do the trick. I recently purchased filter disks and will be cutting them up into little wedges and then adhering them to autoclavable plastic lids. With the remainder of my sawdust spawn (pink, blue, and gold oyster) I plant on directly inoculating straw without expanding on grain, then doing tissue cultures from the fruit, then onto grain/popcorn to start my own grain cultures.

I am a little frustrated with my failed grain spawn attempts, but I guess this is part of the learning curve, and will prove tremendously rewarding when accomplished.

Good stuff! Ya I was going to say something about going from sawdust-grain not being a great idea. I have heard in the past that it is not recommended, but I am not sure why. Perhaps because there is inherent contamination that can survive on the sawdust spawn in some form, not bothering healthy mycelium, but when it gets onto nutritious grain it is allowed to proliferate. Just a guess though. I think the measures you are going through to clean you lab area might be unnecessary, as the problem is likely somewhere else. I have made make shift labs in garages, bedrooms, offices, with dogs running around ect. but as long as your main work area is clean ( and using a hood) you should be OK. On a small scale of course. It’s good to be clean, but again, your problem likely won’t be solved by deep cleaning the lab.

For cleaning out used jars, just simply wash them with soap and water. You will be sterilizing again anyway, so they don’t have to be 100% clean. But I always replace the poly filters, not sure if that is necessary either.

I think you will have good luck spawning directly to straw. Happy growing!

Place lid rubber side up 🙂 trust me.

Hi there and thanks for all the great info. Im just trying to get geared up for my first oyster grow. I want to use a 41qt canner. The plug-in all American. Wondering if you might know what kind of breaker to run that big canner on.

Thanks again to fresh cap for the great info.

Hey Dale,

Thanks for reaching out! You should check the amperage draw for that canner, looking on Amazon.com, it says that the 120 V version pulls 6.88 amps. I am not an electrician, but most house circuits are 15 Amp, meaning you should be fine to run the canner, as long as there isn’t much else also pulling power on that same circuit.

Hope that helps!

Hey I have a question about rusty pressure cookers. Would it be silly to use one ?

Hey Jessie!

Personally, I wouldn’t use it. Pressure cookers can be dangerous if they are in poor condition, best to get a new one!

My friend let me us his Nutritionist brand programmable pressure cooker, it’s electric plug in with a simple digital panel. Unfortunately there is no PSI sensor. I’m using it for 2 mason jars of grain innoculate with 1 cup of water added fir steam. I used the cook mode and steam setting. The max time it will cook is 99 mins. I hope this works, have you heard anything about this model cooker before? Any tips or suggestions?

Hey Daniel!

Thanks for reaching out! No, I have not heard of this type of cooker before… that being said, if you are just doing 2 mason jars it should be fine even at lower pressure. 15 PSI is recommended, but you can often get away with less.

Hope that helps!

Tony

Hey Joe! Looks like you need a electric burner- the kind people use on counter tops if they don’t have a stove. I have tried this before but couldn’t find one that is powerful enough to actually bring the cooker up to pressure. I am sure there is one out there though!

Hi, Tony,

I have some questions about mane lion mushroom.

My pressure cooker is running by electric power instead of stove top. It’s only 5 liter, reaching up only to 10 PSI.

How long shall I cook to fully sterilize a 5 lb fruit block?

After the fruit block is inoculated by grain spore, shall I put the bag at the more humid place for better colonization or just leave it anywhere at home?

During colonization, do I need to monitor the environment condition like temperature and humidity as well?

I’m living Fresno of California, very dry place. I’m not sure if the water inside of bag is gonna dry out.

Hey Jun! Thanks for reaching out! You should be able to sterilize the fruiting block in 2.5 hours, but you’ll have to do some experimenting to find out what works for you. After you inoculate the block with spawn, you can just leave it on a shelf in normal room temperature and humidity. All the humidity that the block needs will already be contained inside the bag. Happy growing!

I just purchased a 41qt All American Pressure Cooker (non-electric) to sterilize my spawn bags. I am curious if this size is also not suitable for outdoor propane stoves. Also, the metal insert that came with it is very different than the one I see pictured in your photos/ videos. Does anyone have experience using this model?

hi tony man! how about a higher pressure. i bought a pressure cooker which operates on 126-129C -22-25 psi and i am wondering if it will damage the grains when i am cooking them. cheers for the answer

Hey there! I am sure that is fine- I don’t have any direct experience with pressures beyond 20 PSI, but I think you should be fine. Worth a try!

This whole blog is an amazing resource. thank you for all you do. i have a question, i have an induction stove top. Do ANY of the pressure cookers work on it? The bottom would have to be magnetic stainless steel or cast iron.

How do you pack bags into a pressure cooker? Is it important to make sure the bags don’t touch the sides of the Pressure Cooker? I made some sawdust bags last year and then ended up quite warped. Wanting to know how I can avoid that. 🙂

Thank you for the great information!! I definitely learn a ton from your collection of awesome knowledge! Thank you again.

Have a question, if you order a bag of substrate, is it ready to inoculate

Or put it in the pressure cooker again Is it ok to sanitize twice

I just bought the 23 quart Presto pressure cooker as suggested.

I have a 20 pound bag of Oak pellets mixed with a small amount of soy hulls. And a few bags of organic wheat bran.

10 Heavy duty spawn bags

I have a 5 pound bag of millet spawn fully colonized with Lions mane.

I should be able to make 5, 5 pound bags of pellets.

The question is how much millet spawn should I put in each 5lb bag of pellets?

If I divide it evenly that’s 1 pound of spawn per bag. Which seems like a lot.

I can easily get more pellets and expand if necessary.

Okay. I GREATLY underestimated how much the Oak pellets were going to expand, and increase weight. I used about half the 20lb bag, and with water and wheat bran that turned into 40 pounds of material. I have 8, 5 pound bags full. Haaha.. Good thing I didn’t buy 2, 20 pound bags of pellets.

Does anyone know how many 5lb blocks or substrate will fit in a 25 quart all american pressure canner